More than just a delivery

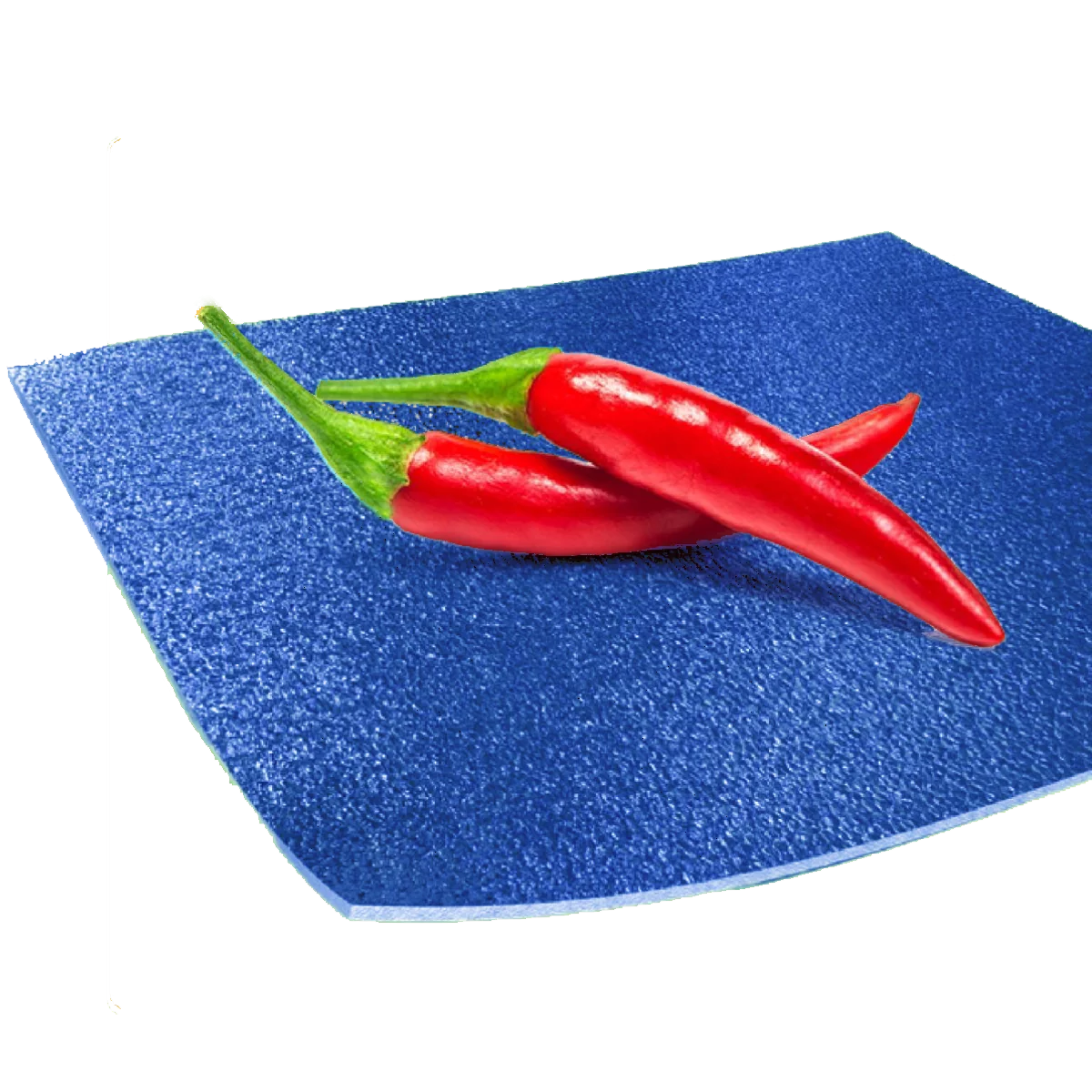

Abriso Jiffy’s specialised packaging materials also plays an important role in the food industry.

Paying great attention to food safety and the quality of food in general, we at Abriso Jiffy are perfectly capable of developing a product that perfectly protects vegetables, fruit and other food products. Since the right packaging allows us to better protect food products, we can also keep them fresh for longer and thus contribute to less waste.

Food deserves protection

Food packaging and all materials that ensure the protection of food products (coolers, cool boxes, preformed packaging, etc.) play a vital role in protecting food products from contamination, maintaining quality, extending shelf life and meeting regulatory requirements. It not only ensures food safety, but also increases ease of use and longevity in the market. This makes our products an integral part of the food industry.

Applications of our products:

We have a wide range of products available for the food industry, from the individual protection and transport of fruits, vegetables,… to the insulation of cold stores and food trucks,… Our applications are endless.

Hungry for more?

About our technology

Protective food packaging comes in different forms, depending on your specific needs and requirements. They can be made of bubble wrap, PE foam and come in a variety of sizes and formats. But it’s not just about the product itself. Our XPS, for example, is also used in refrigerators, cool boxes, protective cases, …

If you are looking for protective packaging for food, take into account the type of food you are packing, the specific requirements (such as refrigeration, shelf life, durability, etc.) and any applicable guidelines. This will allow you to choose the most suitable packaging or protective materials for your products.

Packaging catalogue

Of course we can pack everything! Check out our full range of protective packaging

Protective packaging and insulation

materials. Protecting the world around us

Abriso Jiffy is specialised in the extrusion of polyethylene (PE), polypropylene (PP) and polystyrene (PS) into technical foam solutions, profiles, foam and air bubble products as well as flooring underlay, insulation boards and tubes.